Inspection and Equipment Overhauling

Inspection and Equipment Overhauling

RIGZONE OVERSEAS specializes in providing comprehensive rig inspection services and overhauling and maintenance for all rig equipment.

Service Performance

1. Initial Inspection

- • Visual Assessment: Technicians conduct a thorough visual inspection of all rig equipment, identifying signs of wear, damage, or corrosion.

- • Functional Testing: Equipment is tested under operational conditions to assess performance and detect any malfunctions.

2. Disassembly

- • Careful Disassembly: Equipment is carefully disassembled to avoid damage to components. Each piece is cataloged for efficient reassembly.

- • Cleaning: All parts are cleaned using appropriate solvents and equipment to remove dirt, grease, and contaminants.

3. Repair and Replacement

- • Component Evaluation: Each component is evaluated for repairability. Damaged parts are either repaired or replaced with OEM (Original Equipment Manufacturer) parts.

- • Precision Machining: For components requiring machining, precise specifications are followed to ensure compatibility and performance.

4. Reassembly and Testing

- • Reassembly: Components are reassembled according to manufacturer specifications, ensuring all bolts, seals, and fittings are secure.

- • Final Testing: A final operational test is conducted to verify the functionality and safety of the equipment.

5. Documentation

- • Maintenance Records: Detailed records of the work performed, including parts replaced and maintenance schedules, are documented for future reference.

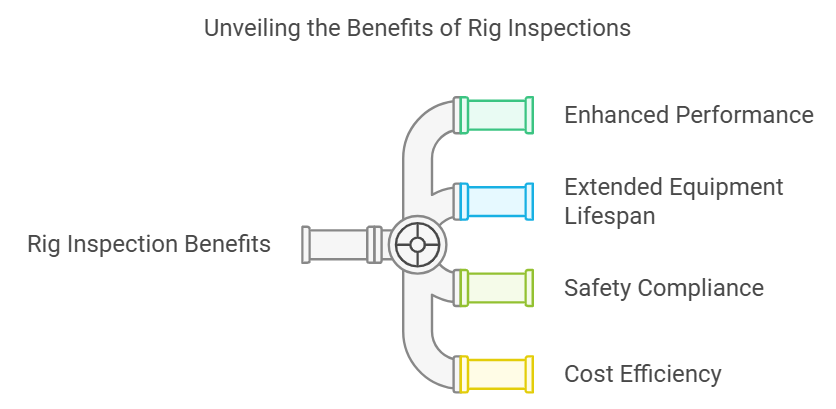

Improvements and Benefits

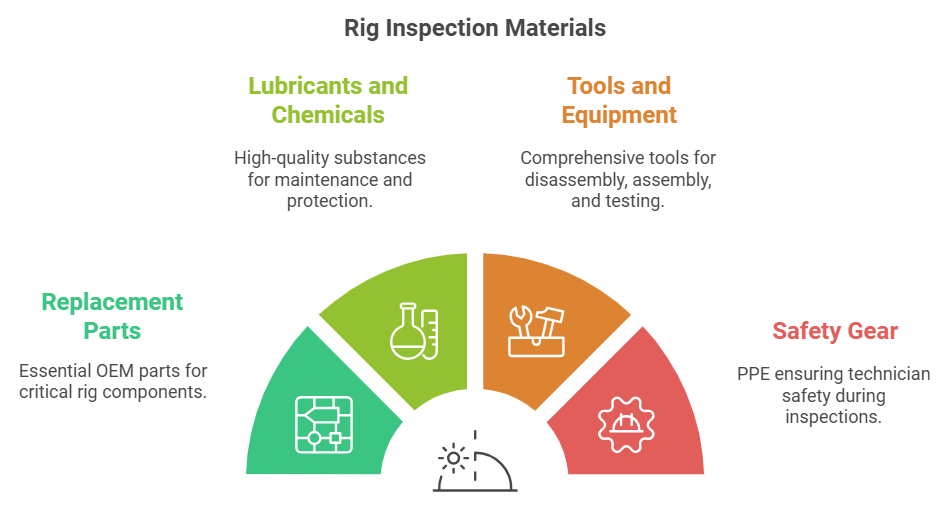

Materials Required

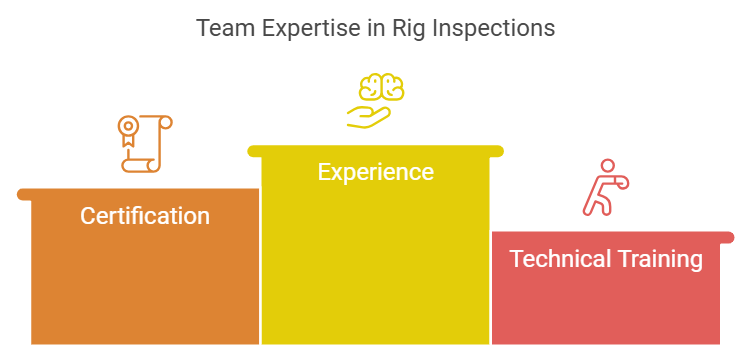

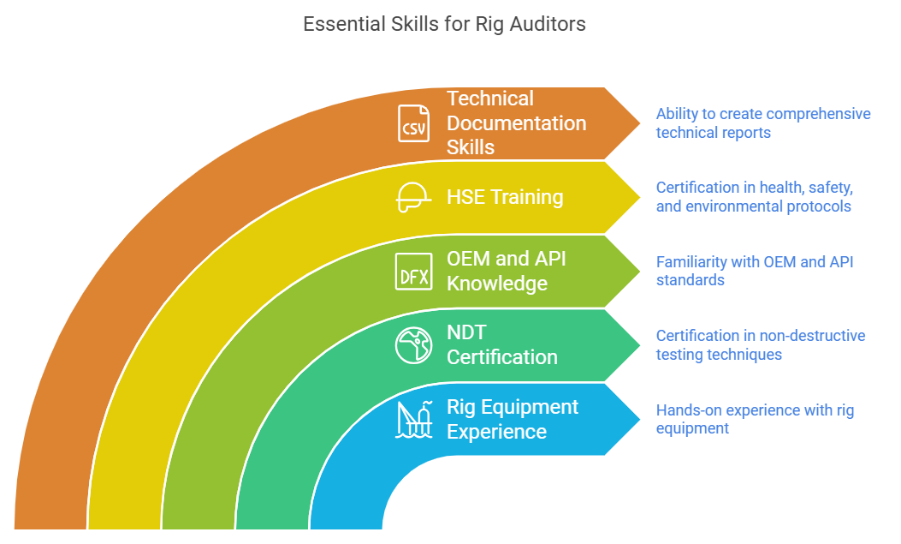

Knowledge and Expertise

Auditor Experience and Expertise

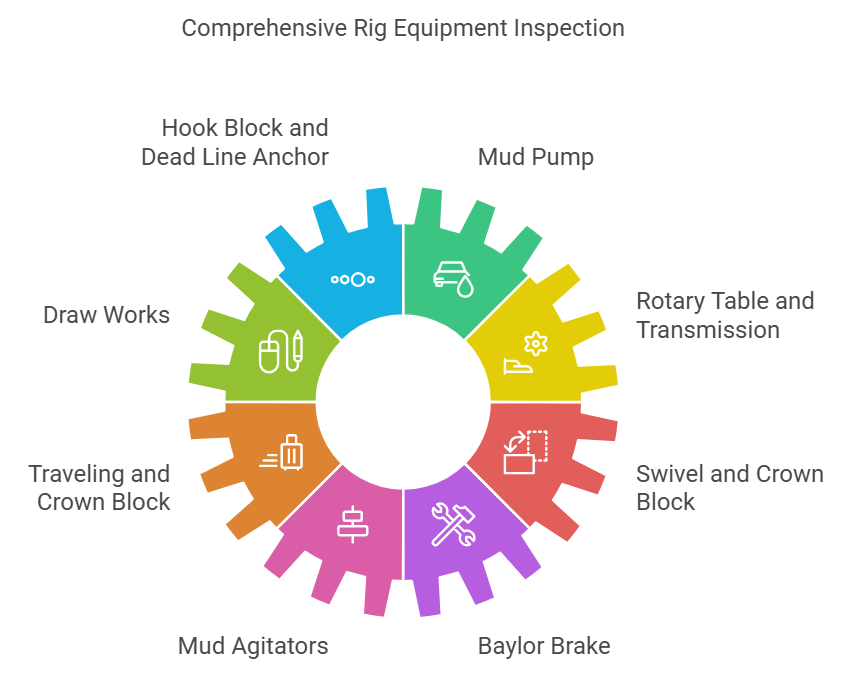

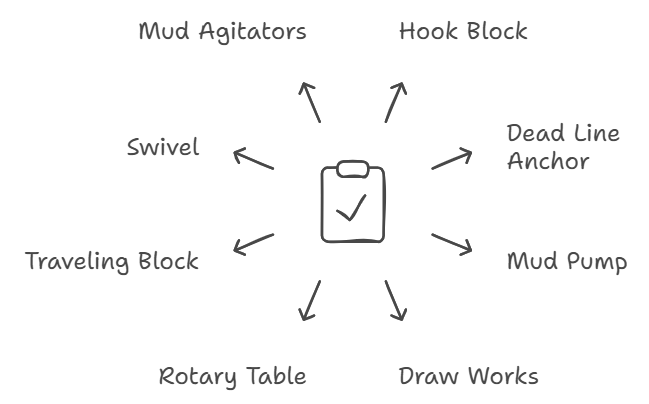

Equipment Inspected

How Equipment Inspected in the Overhaul