RI-Vocational information

Rig Inspection

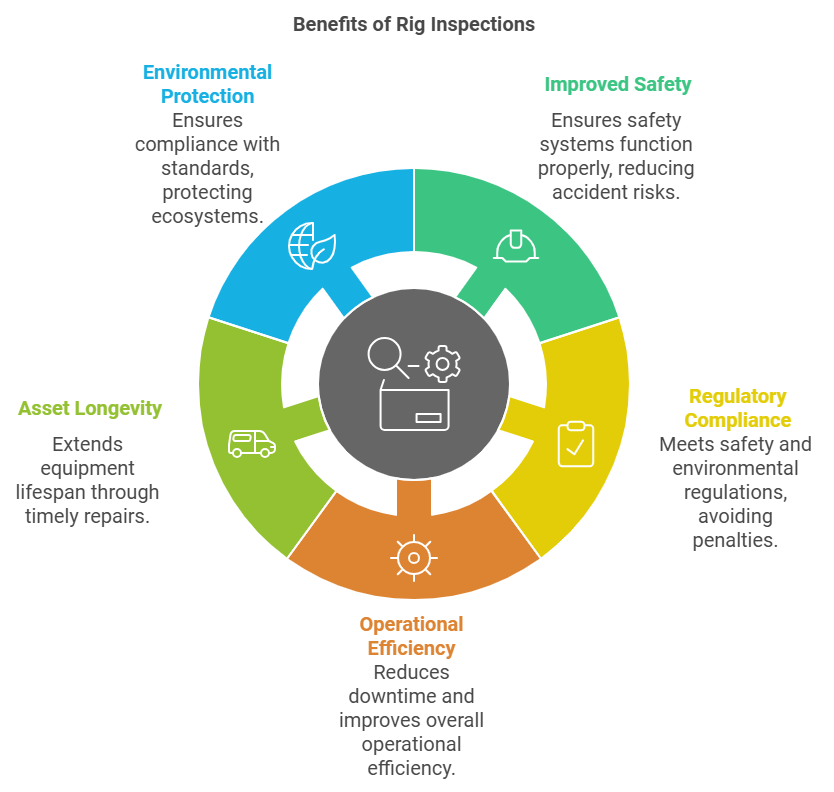

Rig inspection services are a critical component of the oil and gas industry, ensuring that drilling rigs, offshore platforms, and related equipment are operating safely, efficiently, and in compliance with regulatory standards. These inspections help prevent accidents, reduce downtime, and extend the life of equipment. Rig inspections are typically carried out by specialized professionals who assess the structural integrity, safety systems, and operational conditions of the rig.

Conducted before a rig is mobilized for a new job or begins operation, these inspections verify that all equipment and systems are fully operational and meet safety standards. This inspection is essential for ensuring the rig is fit for purpose and reducing the likelihood of operational failures during drilling.

PRE-OPERATIONAL INSTRUCTIONS

These inspections are scheduled on a regular basis (e.g., weekly, monthly, quarterly) to monitor the ongoing condition of equipment and identify any signs of wear, damage, or deterioration. Routine inspections are essential for ensuring that safety systems, critical infrastructure, and operational equipment remain in optimal condition.

Routine Operational Inspections

More comprehensive than routine inspections, annual inspections typically involve a detailed review of the rig’s safety, mechanical, and electrical systems, as well as structural integrity. These inspections may require a team of inspectors and specialists to conduct thorough assessments of critical components, such as the blowout preventer (BOP), lifeboats, cranes, and pipelines.

ANNUAL INSPECTIONS

Regulatory bodies, such as the U.S. Bureau of Safety and Environmental Enforcement (BSEE), the International Maritime Organization (IMO), and other national or regional authorities, require specific inspections to ensure compliance with industry standards, environmental regulations, and safety protocols. These inspections are mandatory and may result in certifications that allow rigs to operate legally.

REGULATORY COMPLIANCE INSPECTION

After any incident, accident, or near-miss, a thorough investigation and inspection are conducted to assess damage, determine root causes, and recommend corrective actions to prevent future occurrences. This is a reactive form of inspection triggered by an event that raises concerns about equipment integrity or safety.

POST INCIDENT INSPECTIONS

These inspections focus on specific equipment or systems, such as non-destructive testing (NDT) of structural materials, inspections of safety barriers and fire suppression systems, or testing of critical components like pressure relief valves, generators, and control panels.

SPECIALIZED INSPECTIONS

Components of Rig Inspections

1. Structural Integrity

Inspectors assess the rig’s structural components, including the derrick, legs, jack-up systems, and subsea structures (for offshore rigs). Any signs of corrosion, cracking, or deformation are documented and prioritized for repair or maintenance.

2. Mechanical and Electrical Systems

This includes checks on engines, generators, pumps, motors, hydraulic systems, and electrical circuits. Proper functioning of mechanical components ensures the rig can operate efficiently, while electrical inspections are crucial for preventing fires, explosions, and system failures.

3. Safety Systems and Equipment

Safety systems, such as blowout preventers (BOPs), fire suppression systems, lifeboats, life rafts, personal protective equipment (PPE), emergency evacuation routes, and alarms, are tested for compliance with safety regulations and operational readiness.

4. Environmental Compliance

Inspections ensure that the rig’s operations comply with environmental protection regulations, particularly in offshore operations. This includes evaluating waste management systems, spill prevention measures, and emissions control systems.

5. Operational and Control Systems

A critical part of the inspection process is assessing the rig’s operational control systems, including its monitoring and diagnostic systems, communication equipment, and automation features. These systems are essential for controlling the rig’s operations, ensuring safety, and maintaining data integrity.

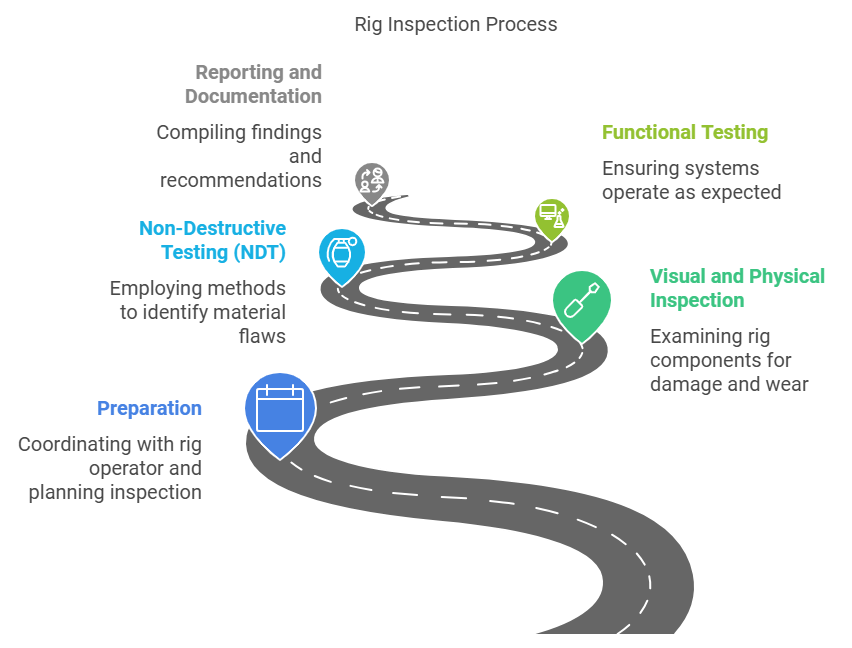

The rig inspection process generally follows these steps

The rig inspection process generally follows these steps

References Used in Rig Inspections

Rig inspections are carried out according to various international standards, industry regulations, and best practices. The purpose of these inspections is to ensure compliance with safety, environmental, and operational standards, identify maintenance needs, and assess the overall integrity of the rig. Below is an outline of the typical references (standards, codes, and regulations) used for rig inspections and the specific parts of the rig that are inspected, along with the relevant references associated with each part.

| Title | Data |

|---|---|

| Parts Inspected |

• Derrick (or mast) |

| References |

• API RP 2A-WSD: Recommended Practice for Planning, Designing, and Constructing

Fixed Offshore Platforms* (American Petroleum Institute). Provides guidelines

for structural design and safety of offshore rigs. |

| Title | Data |

|---|---|

| Parts Inspected |

• Engines and generators |

| References |

• API 6A: Specification for Wellhead and Christmas Tree Equipment (American

Petroleum Institute). Covers the specification and inspection standards for wellhead

equipment, including valves, control systems, and actuators. |

| Title | Data |

|---|---|

| Parts Inspected |

• Blowout preventers (BOPs) |

| References |

• API 53: Blowout Prevention Equipment Systems for Drilling Wells (American

Petroleum Institute). Provides guidelines for the design, maintenance, and testing

of blowout preventers and related systems. |

| Title | Data |

|---|---|

| Parts Inspected |

• Waste management systems |

| References |

• IMO MARPOL Annex I-V: International Convention for the Prevention of Pollution

from Ships (International Maritime Organization). Contains regulations for the

prevention of marine pollution, including waste management and oil spill

prevention. |

| Title | Data |

|---|---|

| Parts Inspected |

• Drilling control systems |

| References |

• API 17F: Recommended Practice for Subsea Production Systems (American Petroleum

Institute). Includes guidelines for subsea production systems and their control

systems, including sensors and alarm systems. |

| Title | Data |

|---|---|

| Parts Inspected |

• Inspection records and logs |

| References |

• ISO 9001: Quality Management Systems – Requirements (International Organization

for Standardization). Defines requirements for a quality management system,

including documentation practices for inspection and reporting. |